·The dismantling fixture can be replaced with a universal automatic screen dismantling equipment. The three-stage parameters of the equipment dismantling process can be adjusted, and the dismantling parameters of each section can be set according to different process requirements to improve the dismantling yield. The screen dismantling process is monitored in real-time with a buffer function for disassembly. The preheating time of components is automatically monitored to prevent insufficient preheating from causing disassembly defects. The dismantling yield of TP modules and middle frame components is lower than 5%

·Disassembly fixture replaceable universal automatic screen dismantling equipment

·The three-stage parameter of equipment disassembly process can be adjusted, and the disassembly parameters of each section can be set according to different process requirements to improve the disassembly yield

·Real time vacuum monitoring during screen disassembly process, equipped with disassembly buffer function

·Automatic monitoring of component preheating time to prevent poor disassembly caused by insufficient preheating

·Ultra high disassembly yield: TP module and middle frame components have a disassembly failure rate of less than 5%

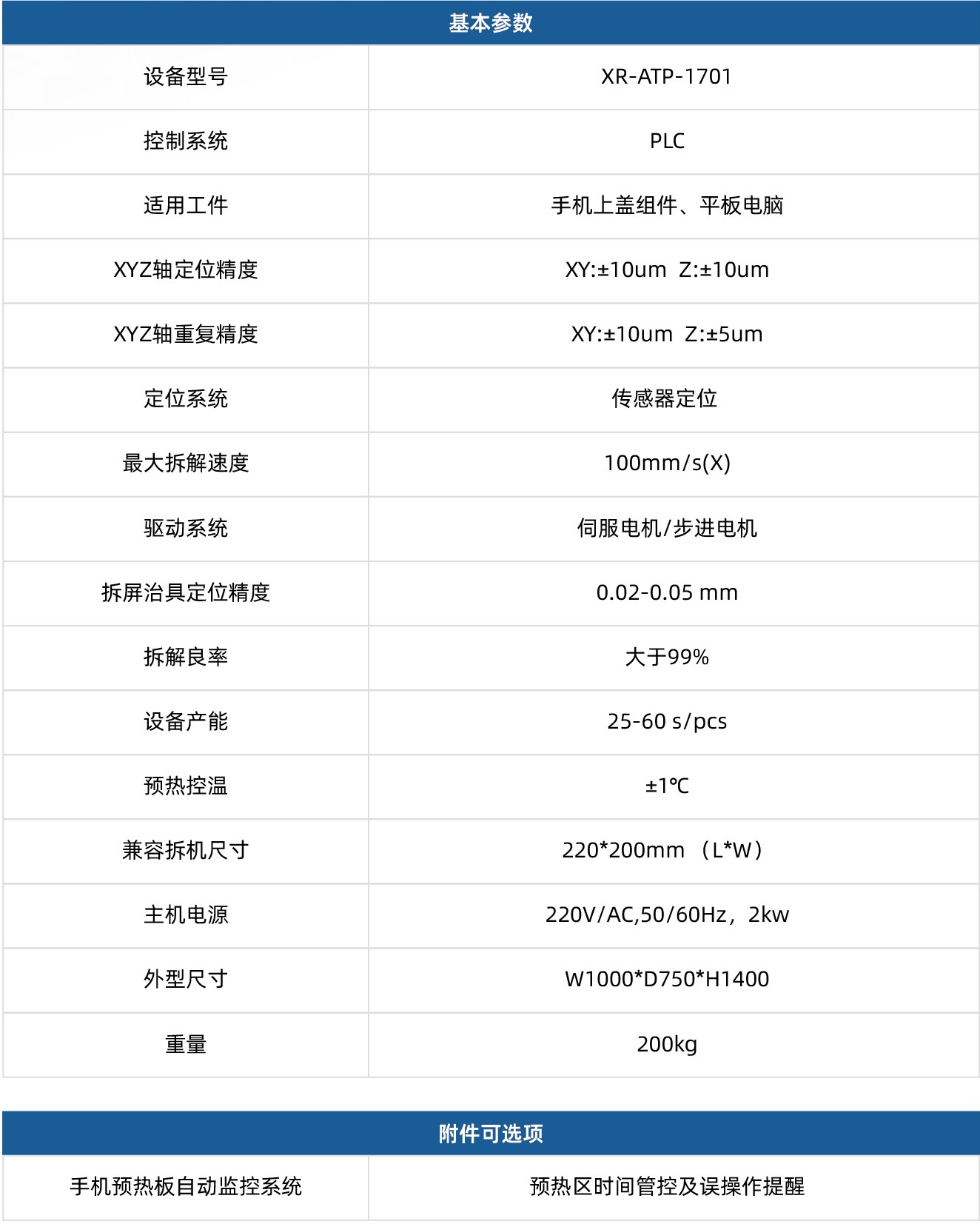

Application scope

The TP module and middle frame of the upper cover component applied to various mobile phones and tablets automatically preheat and separate for disassembly.