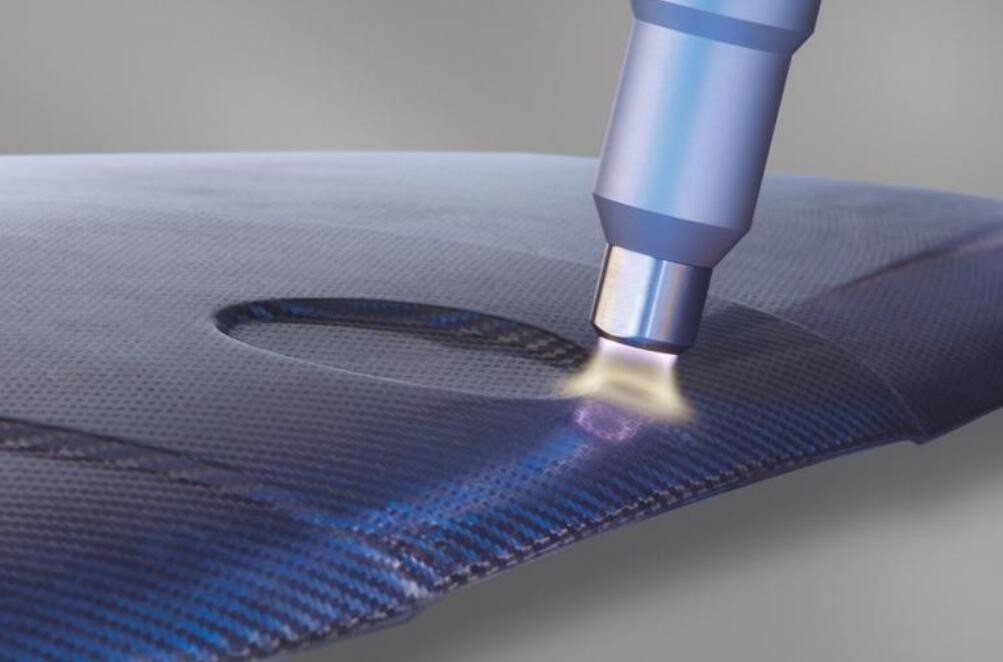

Application of plasma cleaning in automobile manufacturing:

PE, PP, PS, and EPDM materials face various challenges during processing due to their low surface energy, making it difficult to achieve good results in bonding, coating, printing, and polishing. Therefore, it is necessary to perform surface treatment on these materials to increase surface energy. Plasma and corona treatment can alter the chemical structure of plastic material surfaces, increase surface energy, and thus enhance adhesion and wettability. Plasma surface treatment is an ideal surface treatment solution for the automotive industry:

1. Uniform and consistent treatment of all surfaces of 3D parts (with robotic arms or visual guidance)

2. Processing specific parts on 3D components

3. Handling large components

4. Clean metal surfaces

5. Surface modification without affecting loose materials

6. High cost-effectiveness and long-lasting adhesion

7. Green and environmentally friendly, in compliance with relevant legal requirements

Plasma surface treatment is suitable for surface activation of the following products:

1. Interior parts

2. Exterior products

3. Power system components

4. Control unit components

5. Lamp and connector components