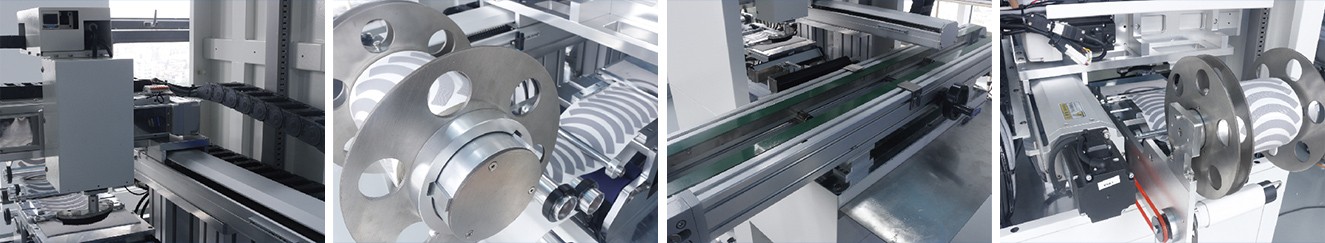

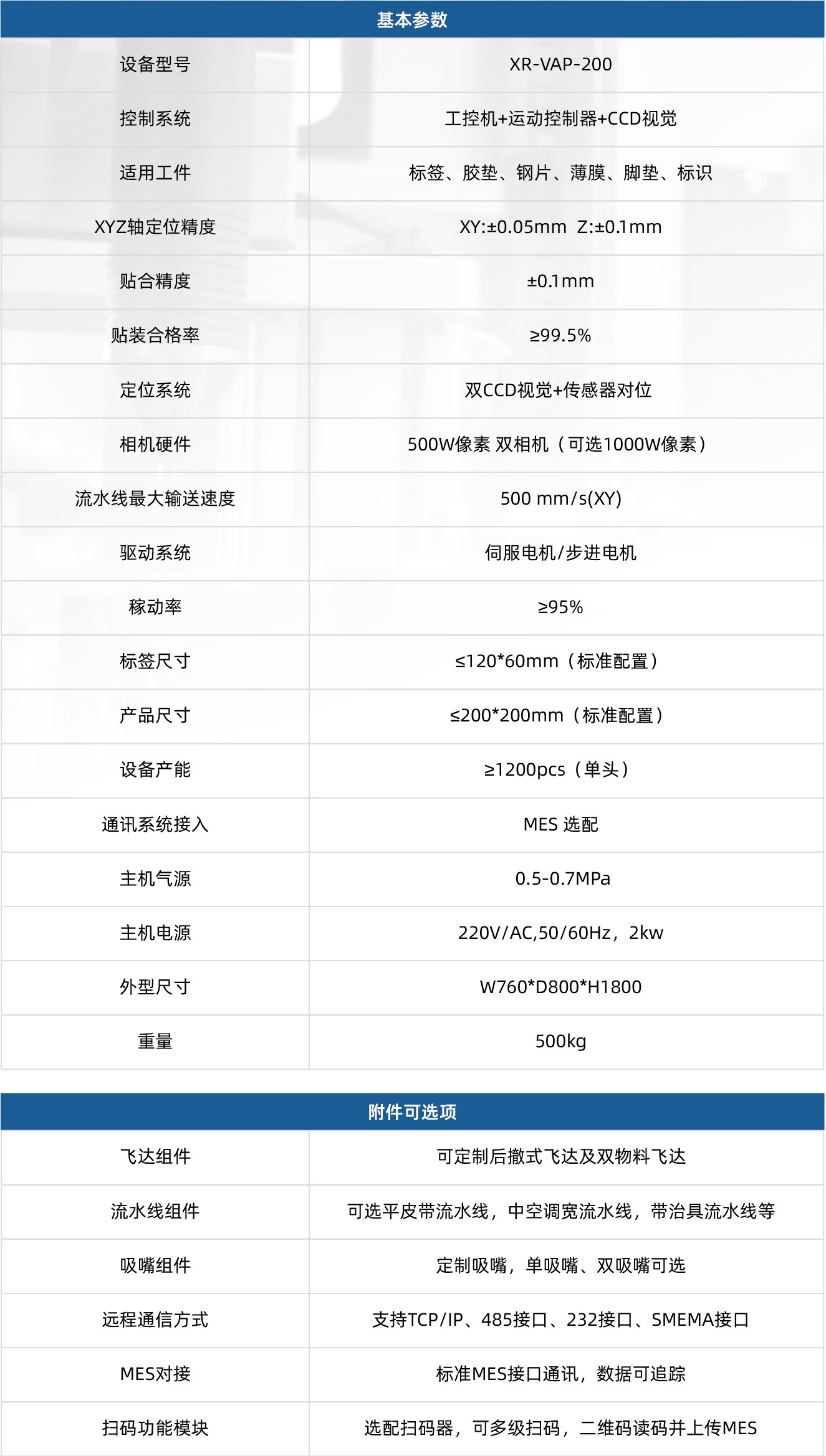

·Online fully automatic visual product positioning with no restrictions on product direction. Optional dual nozzle feeding and dual Feida feeding can be used, and different materials can be conveyed on the assembly line without the need for tooling, with high universality. Label auxiliary materials can be peeled off by Feida, CCD visual secondary alignment can be achieved with high precision. Productivity can be improved by reducing manual intervention and increasing equipment utilization rate. Multi functional collection. Optional MES communication and equipment remote communication protocols can be used to upload important parameters of equipment operation in real time. Application range: labels, auxiliary materials, foot pads, and films can be attached to devices such as mobile phones, tablets, laptops, toys, smart terminals, medical equipment, security products, industrial accessories, TP, etc

·Online fully automatic visual product positioning, unlimited product direction

·Optional dual nozzle feeding and dual Feida feeding, while fitting different material conveyor lines, no need for tooling, high versatility

·Label accessory Feida peeling, CCD visual secondary alignment, high-precision bonding

·Improve productivity: reduce manual intervention, increase equipment utilization rate, multifunctional integration

·Optional MES communication and remote communication protocols for devices, allowing for real-time upload of important operational parameters

Application scope

Labeling accessories, foot pads, and films, such as mobile phones, tablets, laptops, toys, smart terminals, medical devices, security products, industrial accessories, TP, PCBs, etc