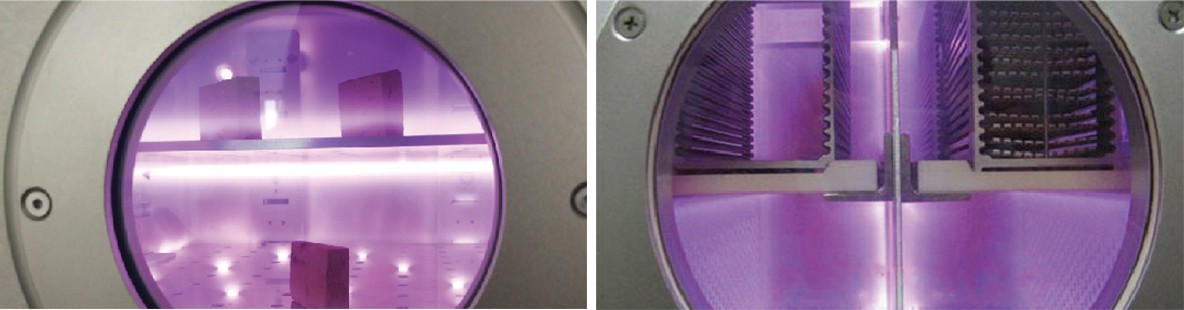

·Large processing space, increased processing capacity, using PLC+touch screen control system to accurately control equipment operation. Equipment cavity capacity and number of layers can be customized according to customer requirements to meet customer needs· Low maintenance and repair costs, facilitating customer cost control· High precision, fast response, good handling and compatibility, complete functions and professional technical support. Wide range of materials can be processed. For precision components and irregularly shaped products, immersion processing can be achieved with uniformity of over 90%

·Large processing space, increased processing capacity, adopting PLC+touch screen control system, precise control of equipment operation

·We can customize the device cavity capacity and number of layers according to customer requirements to meet their needs;

·Low maintenance and repair costs, facilitating customer cost control;

·High precision, fast response, good handling and compatibility, complete functions and professional technical support

·Wide range of materials that can be processed

·For precision components and products with irregular appearance, immersion treatment can be achieved

·Uniformity of over 90%

Application scope

Suitable for the printed circuit board industry, semiconductor IC field, silicone, plastic, polymer field, automotive electronics industry, aviation industry, etc. Printed circuit board industry: high-frequency board surface activation, multi-layer board surface cleaning and de drilling, soft board and soft hard bonding board surface cleaning and de drilling, activation before soft board reinforcement. In the semiconductor IC field, COB, COG, COF, ACF processes are used for cleaning before wire bonding and soldering. In the polymer field, surface roughening, etching, and activation of silicone, plastic, and polymer are used.