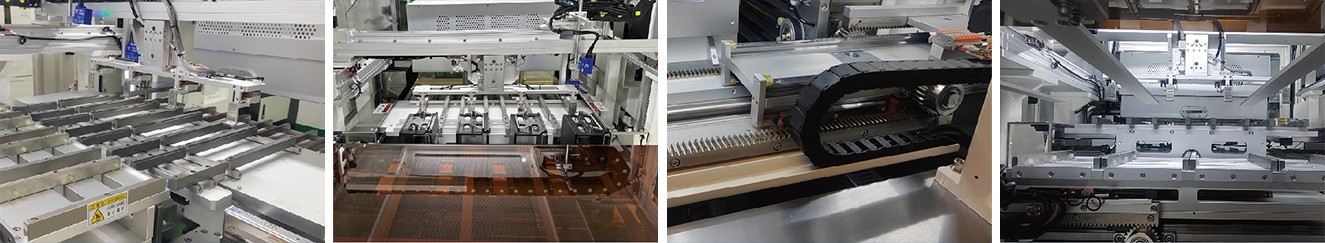

·Online fully automatic track width adjustment+high-speed plasma cleaning · Improve productivity: reduce manual intervention, improve equipment utilization rate, multifunctional collection, optional multi-channel multi-layer processing · Built in FFU air purification module to ensure clean processing environment and reduce dust particles · Optional MES communication and equipment remote communication protocol to upload important parameters of equipment operation in real time. Application scope: Semiconductor related devices such as IC chips, power devices, sensors, optical communication modules, IGBTs, etc. Die bonding, wire bonding, glue dispensing, coating filling, printing, film coating, etc. Pre process plasma treatment.

·Online fully automatic track width adjustment+high-speed plasma cleaning

·Improve productivity: reduce manual intervention, increase equipment utilization rate, multifunctional collection, optional multi-channel and multi-layer processing

·Built in FFU air purification module ensures clean processing environment and reduces dust particles

·Optional MES communication and remote communication protocols for devices, allowing for real-time upload of important operational parameters

Application scope

Semiconductor related devices such as IC chips, power devices, sensors, optical communication modules, IGBTs, etc. undergo plasma treatment before processes such as die bonding, wire bonding, plastic packaging, dispensing, coating and filling, printing, and film coating.